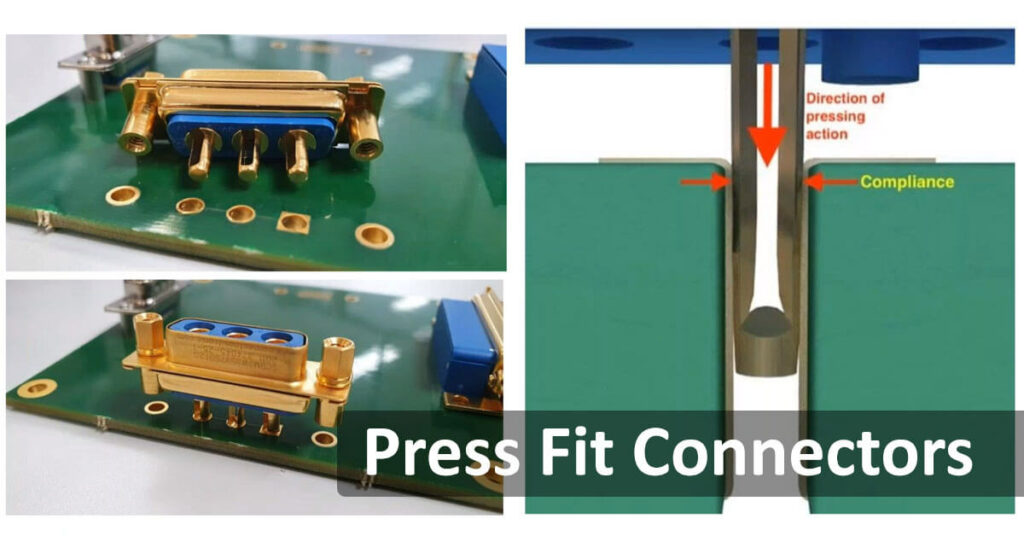

Press fit is an alternative to soldering where the connectors are pressed into either side of a PCB, either manually or in an automated way. Connectors can be easily removed and reinserted–and the failure rate of press fit is 100 times lower than that of soldering.

The tech has been sampled and is reliable in high vibration and thermal cycling environments. Positronic press fit connectors were the first approved for space flight applications; they offer a high quality product. One distinguishing characteristic is the gas-tight connection between contact and plated through hole, among others.

The following recording of a webinar (free) covers not only the concepts of press fit but the logistics of installation such as the requirements and procedures for the support and seating tools, the specs for thickness of PCB board, etc.