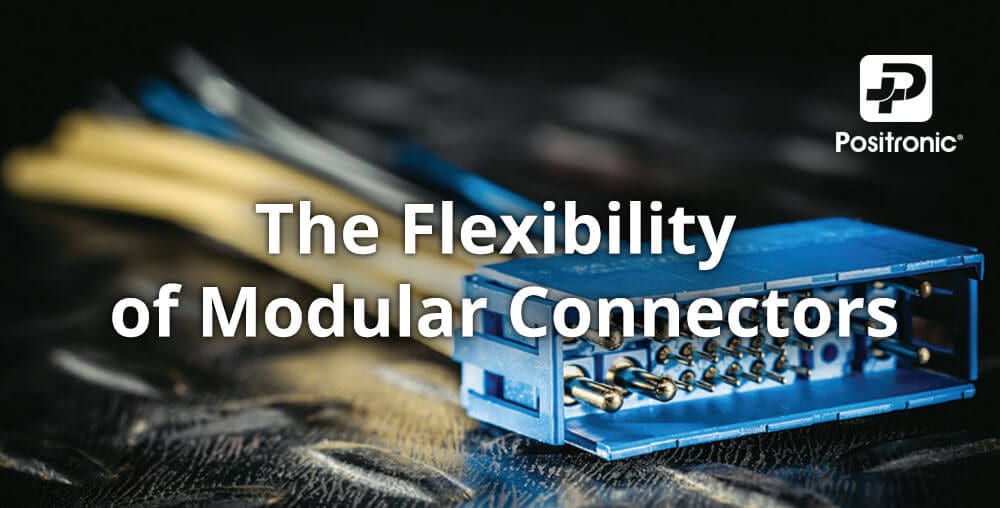

Word from Positronic…

Modular connectors are designed to allow customers to construct a customized design from a range of standard options.

Specifying a new connector is a complicated process. Connectors must work reliably in some of the most demanding environments and applications known to man, which has led to huge variations in connector design. As a result, they can be among the most difficult components for designers to select.

Faced with such a confusing range of options, designers often find it difficult to choose the correct product for their design. Even then, it is possible that the exact combination of options that the customer requires might not be available, even with the entire interconnect industry at their disposal.

The designer must then work with a connector manufacturer to design and create a custom connector. This can be a very costly process, which may force the customer into making a compromised choice. That’s where modular connectors come in.

Introducing Modular Connectors

Many major connector manufacturers have identified this as an issue, and so have created several choices in the area of modular connectors. Modular connectors are designed to allow customers toconstruct a bespoke design from a range of standard options. The components of the modular connector are already designed and ready for manufacture, making it easy for the customer to specify the exact features required. All that the customer need do is choose the options they need to create their perfect connector.

Different manufacturers have taken different paths to create a range of modular connectors. The simplest approach follows a building-block concept. In this case, the manufacturer offers a range of individual modules that perform different functions. The customer must purchase the modules required and arrange them in the order that suits the application. The modules are then secured with a frame to create the final connector.

This concept will be very familiar to anyone who understands LEGO building blocks, and it provides similar advantages – the designer has the ability to build and rebuild their connector to suit future needs. There are disadvantages to this concept, however. The customer must order each of the individual components which will add to inventory and record-keeping complexity. However, the flexibility provided by this system means that the designer can reconfigure the connector by simply taking it apart and starting again. In addition, as the connector is created from a number of components, they must be assembled correctly to ensure the best possible mechanical strength.

At the other end of the scale of complexity is the approach taken by manufacturer Positronic Industries with the Scorpion family. In this system, it is the mold tool itself that is modular. To create a connector, the customer selects the modules needed as before. Positronic then creates the mold tool from a number of standard dies, arranged according to the customer’s design. The plastic connector is then created as a single piece before the contacts are installed,

in a process known as monolithic injection molding.

The body of the Scorpion is therefore a one-piece connector that allows the customer to order a single part number. The designer might lose some flexibility as the connectors are not reconfigurable, but nonetheless the Scorpion is essentially a custom connector without the custom price tag.

The advantages of this monolithic process go beyond the creation of a single part number. Unlike a modular connector that is assembled from several components, the one-piece construction of Scorpion makes it very strong. This is of paramount importance in applications that require connectors to perform reliably in harsh environments, including aerospace and defence where systems must withstand extremes of temperature, vibration and shock.

CONTACT US HERE FOR MORE INFORMATION

Download Positronic’s latest technical article, The Flexibility of Modular Connectors…

_

We are honored to serve as a manufacturer’s rep for Positronic, a global manufacturer of high reliability electronic connectors for use in various applications.