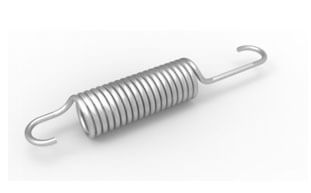

How to design the right types of ends or mating components for the three most popular types of springs: extension springs, compression springs, and torsion springs.

|

|

|

|

| An extension spring is required any time the application calls for a spring that will work in tension. The spring body will be extended during use, so the most common type of ends are hooks. | A compression spring decreases in length during use to provide a deflected force. Like extension springs, they come in all sizes, from little tiny springs that you might find inside of a pen, to huge hot-wound springs that you might find on a train. | A torsion spring is meant to twist, or torque. Instead of being compressed or extended, it’s twisted. Some examples that call for a torsion spring include garage door springs, clothespins, and lift ramps. |

_

We are honored to serve as a manufacturer’s rep for HELI-CAL, an MW Industries brand. Helical has over 50 years of experience designing and producing Flexures for use in products ranging from encoders to spacecraft.