Application Details

Data centers contain multiple racks and cabinets with servers that manage great amounts of data for customers from a wide range of industries including those with highly sensitive information such as medical and financial industries.

Light pipes provide a visual indication of server activity in data centers. The request was for a specific configuration and shape of a light pipe array that prevented any potential light bleeding from the LEDs which indicated activity of specific servers’ function, and also light cross-talk among the light pipes in the array.

Light bleeding or light cross-talk can cause the light from LEDs to send light into other light pipes therefore providing wrong HMI information to the technicians related to server activity.

Application Requirements

The light pipe array required a special shape while also preventing any potential light bleeding and/or light cross-talk among the light pipes. Intensity at the lens also needed to allow for visibility from a specific distance.

The array would also need to be compact and stable to allow for a proper and simple mounting during the server’s manufacturing process, while also avoiding other internal components in the surrounding areas.

Solution & Customization

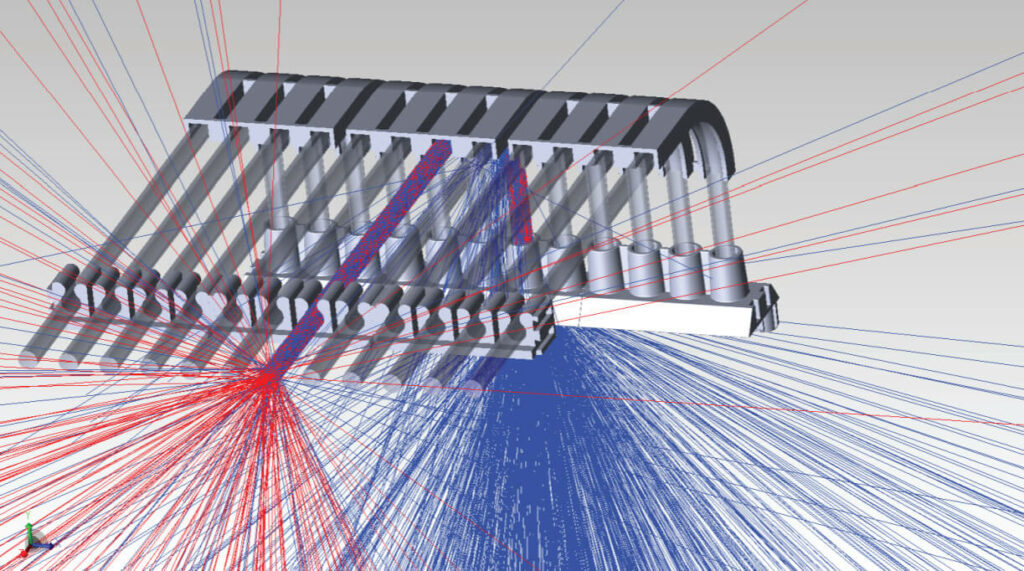

Bivar developed and integrated a custom light pipe array based on trace simulations, which included individual light pipes, a specially designed adapter that would cover the LEDs while allowing full light transmissibility, and a cross bar that stabilized the complete array.

The adapter prevented and significantly reduced the light bleed from the LEDs, the special shaped array also reduced any potential light cross-talk and the stabilization bar enhanced significantly the assembly process into the servers.

All-in-all: Meeting the need

Through Bivar’s engineering excellence and processes, detailed analysis and extensive use of various tools and techniques such as trace simulation, an optimal solution was provided that significantly reduced LED light bleeding and also the light cross-talk which created significant Human Machine Interface (HMI) issues for the HMI compared the original design.

The after service provided the right tools and suggestions on how to properly apply the product to meet the application demands.

ESI is the local representative for Bivar, a trusted provider of high quality enclosure hardware, LED indication, and LED lighting products that are designed to meet the increased demand for innovation across a growing range of applications.